Gemba literally translates to ‘The Real Place’, but in the Kaizen context means the place where the work gets done. The engine room.

The more effective your workspace (both real and virtual), the better off you’ll be.

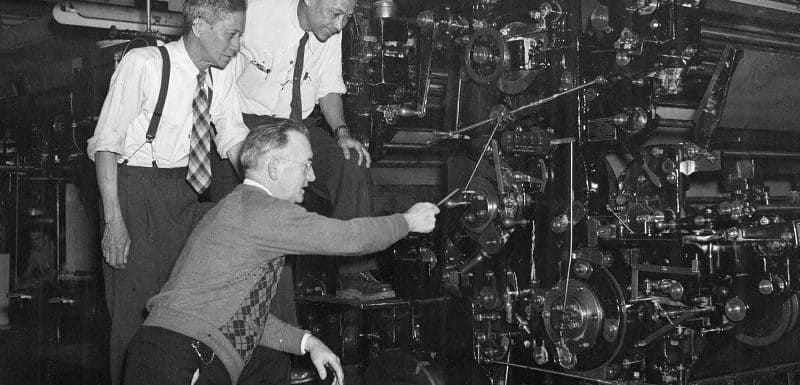

In Kaizen manufacturing philosophy, the ‘Gemba walk’ is a walk through the shop floor to engage those who are doing the work directly and observing the pathway of inputs through to outputs. In doing so, we engage the entire business and everyone has responsibility for improving the process.

In service industries like advice, this doesn’t work in quite the same way. However, this powerful process improvement strategy shouldn’t be dismissed as something we can’t adapt for our advice needs.

Here is one useful way you can leverage the Gemba walk approach in your practice to identify process improvement opportunities.

Physically represent the process in your office

Things are often outside of our control in the advice process, but it may not be as out of control as you think.

Help concentrate your mind on where the process is by representing it with something physical. Find something that stands out. Then nominate a real life instance of a case that’s going through that process. ‘The Penske File’, for example.

What do we mean by something that stands out? Can be anything, the office mascot, something fun, something embarassing, something smelly… the idea is it’s something noticeable that people are going to want off their desk. Could be:

- A witches hat

- A flag

- My Little Pony figurines (a series of things is nice, can be one per client case)

- A cuckoo clock that goes off every hour

- Fruit (a visual and olfactory representation of the process taking too long)

- A metronome (maybe too annoying/distracting)

If you have a My Little Pony figurine of these on a desk, it’s pretty obvious where a process is sitting. You can’t miss it as you move around the office.

If you’re working in a virtual team, you can still engage your virtual team in the same way, or have them set their profile avatar to something silly.

Importantly, this is not a process about blame or personnel management. Everyone should want to move the item off their desk ASAP, but it’s about reviewing the process. It’s important to explain what we’re trying to identify through the Gemba advice walk and that it’s everyone’s responsibility to draw observations.

Identify where things stall, and brainstorm

At least once a week you should be reviewing the outstanding case/cases and brainstorming with your team how things could be done differently.

What is outstanding? Why did the process stay where it did for as long as it did? What could’ve been done differently? What would a lawyer or accountant do at a similar stage? What would Dell, Apple, BMW, or Westfield do?

Example 1

Practice conducts a gemba advice walk and find that things sit with the adviser for a long time. In brainstorming, it’s clear the adviser presents a bottleneck.

- Adviser takes a long time to proofread SoAs. Could SoAs be peer reviewed or proofread by an associate adviser or client services manager first?

- Adviser takes too long to write file notes. Could we record client meetings, take file notes via audio file, or both? Could we invest in file note templates to streamline?

- Adviser takes too long to prepare strategies. Could we invest in developing an advice philosophy to streamline handover to paraplanning and improve compliance/consistency.

Example 2

Practice conducts a gemba advice walk and find that things sit with the administration team for a long time. In brainstorming, it’s clear things are heavily dependent on external providers.

- It takes a long time to collect information from product providers. Could we be getting/sending authorities earlier? Could we ask clients to seek that information (accountants usually put the onus on clients, why can’t we?)?

- It takes a long time to get information from clients. Could we break this up into more manageable pieces? Could we determine what we need ASAP, and what we don’t need until the SoA is being prepared?

- Underwriting takes too long. Could we commence underwriting earlier? Could we encourage clients to press their doctors sooner? Would it be worth paying for the PMAR in high-value circumstances?

If this is all a bit too much for you, a bit too out there, you can consider doing a post-implementation audit. Go back through the file and see what held up the process and where, with that constant mindset: What else could have been done differently?

Nothing here requires large datasets, process management software, or productivity reporting. Of course, those things can help to provide insights into what might be going wrong… but all too often their data is ignored. So and so is busy. That step always takes long. It’s harder to ignore a sparkly pony on your desk and keep from thinking of a way to get rid of it faster.

Leave a Reply